Industrial drainage systems

Be it in food and beverage processing facilities or a pharmaceutical and biotech industries, drainage has a major overall impact on hygiene and safety of the facility, performance and has a critical role when it comes to food hygiene and ultimately public safety.

By taking a rounded approach, we are helping our clients all around the world with:

- establishing better production efficiencies and lower operational costs

- enhance product and employees safety

- provide ultimate range of drainage system products with improved product lifecycle, easy installation, maintenance and warranty

- strong service from design consulting to onsite installation support

With many years of experience and drainage system assesmensts, our team is committed to ensuring all aspects of proper drainage systems are designed, manufactured and catered to business to bring to our clients and their operations peace of mind.

Key decisions to make when specifying industrial drainage system

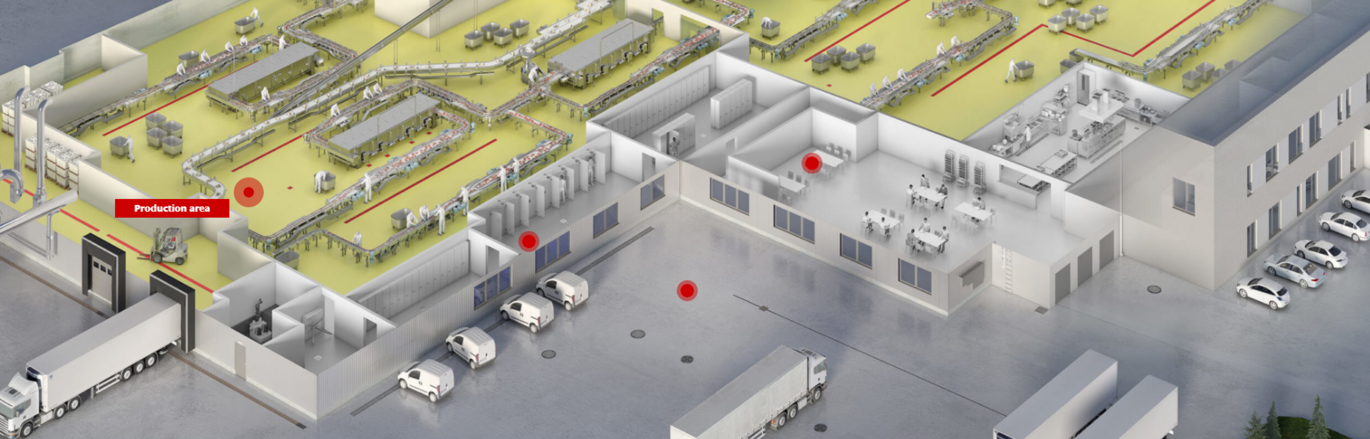

1. Choosing the right design solution

Each facility and individual places in it have their own specific requirements. The production areas in food and beverage facilities comprise high risk zones and as such require high performance hygienically designed drainage systems. Choosing the right type of drainage and its position according to the location of factory equipment is essential to achieve safe environment, avoid production disruptions and unnecessary costs.

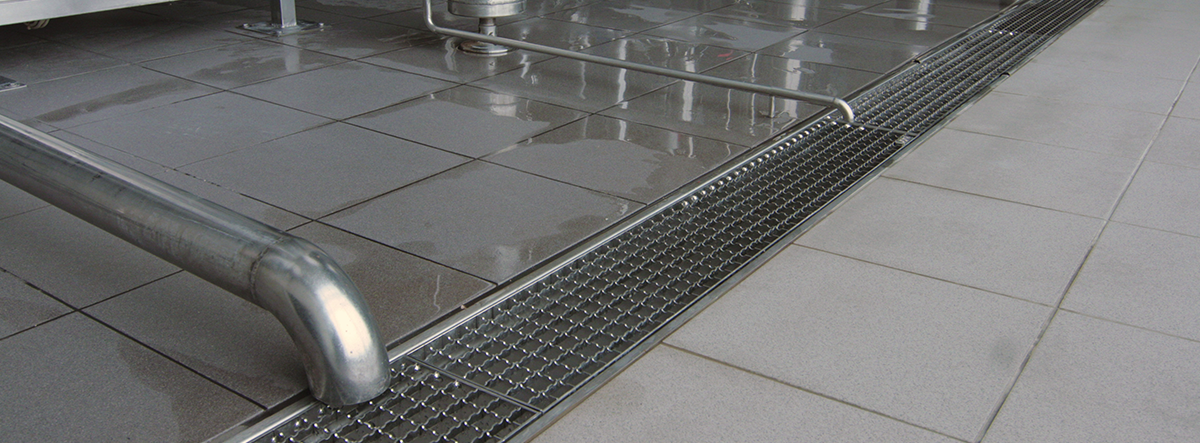

2. Drainage system integration

Well-chosen drainage of the highest quality may not be enough if it is not well connected to the floor and does not form a functional unit with the floor. During its lifetime, the floor will be exposed to variety of elements that are potentially very damaging including hot oils, acidic solutions and organic substances like fat and blood. In addition, the floor will have to withstand cleaning and washing with hot steam and aggressive detergents so the ability of a floor to resist these factors is a critical consideration. Items which are placed on or fitted into a floor such as machinery, trays and drainage can also increase the potential for flooring defects to occur. To prevent any defects occurring, the drainage specification must be considered with regard to the type of flooring specified and the features of it.

3. Sufficient drainage flow capacity

In production areas in food and bevarage facilities, the drainage system must be able to drain large amounts of water in a very short time. Insufficient drainage capacity leads to flooding which compromises health and safety in the workplace and increases the risk of cross-contamination. It’s important to ensure the layout of the drainage matches the layout of the production equipment. Put simply, if equipment is placed on top of the drainage or drainage is not easily accessible, the drainage system may not work correctly, may be hard to maintain and impossible, or at least difficult, to clean. Both the layout of the factory equipment and the drainage system needs to be considered right at the start of a project.

4. Waste water management

In some areas, such as food and bevarage production, water is not the only thing that gets into the drainage. Waste debris including meat, vegetable leaves and solids including etiquettes, glass shards and bones frequently fall onto the floor and clog the conventional silt basket in very short time, creating frequent maintenance requirements. As the water cannot now drain away, it causes delays in production, compromises site safety and greatly increases the risk of contamination. To prevent this, it is appropriate to use solutions developed for this purpose.

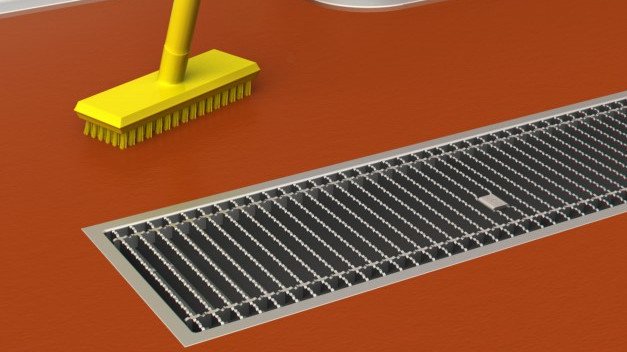

5. Cleaning effectiveness

Drainage is a critical component affecting the hygienic performance of any commercial food preparation business. Effective drainage helps to mitigate hazards from the external environment and is central for safe and hygienic operations. Recent research conducted with the Fraunhofer Institute found that hygienically designed drainage can be fully cleaned in just 8 minutes, whereas non-hygienically designed drainage could not be fully cleaned even after 180 minutes of cleaning!

6. Load class

The grating itself is the most exposed part of a gully or channel in regards to site traffic. To minimize the risk of failures, a proper grating type and load class have to be considered based on current and likely future traffic requirements for all operations.

Downloads

- Five crucial factors for selecting a perfect Grease Separator

- How to choose a right lifting station?

- ACO Commercial Kitchen Guide

- ACO Leaflet Commercial Kitchen 210x297 24p 2018 Preview

- HygieneFirst - Brochure

- ACO Box Channel Gully Top

- ACO Grating Selection Guide

- ACO Hygienic Gully - Telescopic Gully Manual

- ACO Waste Water Lifting Station 2020 ENG

- ACO Kerb V4

- ACO Pipe Brochure 2018 Q2 V02

- ACO Food Beverage Web

- Ultimate Hygienic Performance-Beverage 2018 EN