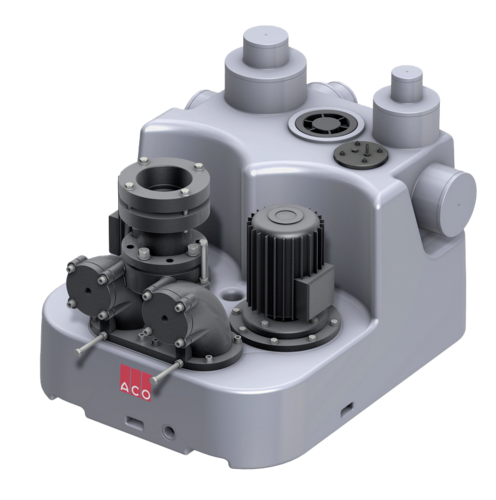

ACO waste water lifting plant Muli-Star DDP

Product benefits

- Low weight

- Different inlet heights

- CFD-optimised impeller

- High chemical resistance of all components

- Suitable for use downstream of grease separators

- Fast installation

- Ready to connect

- High usable volume – up to 185 l

- Adapted to door dimension: 780 mm

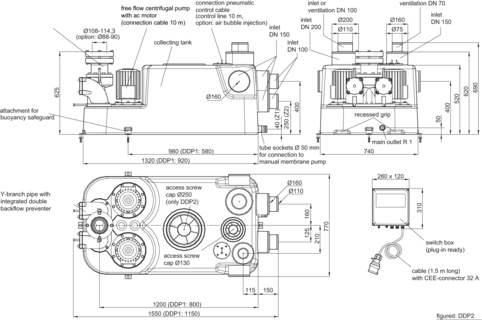

Product information

- Areas of us

- Downstream of grease separators up to NS 15 – in conjunction with air bubble injection

- Multiple dwelling units

- Office buildings, hotels

- Hospitals

- Tank made of polyethylene

- Bottom outlet R 1"

- Inspection opening for easy maintenance, diameter: 130 mm (DDP1), 130 mm and 250 mm (DDP2)

- Fixing set for buoyancy-proof anchorage

- Connection for manual diaphragm pump DN 50

- 2 horizontal inlet sockets, DN 150

- 2 horizontal inlet sockets, DN 150/DN 100

- 1 vertical inlet sockets DN 200/DN 150

- 1 vertical inlet sockets DN 100/DN 70 - 1 ventilation socket

- Delivery line connection

- Special backflow valve with ball in the housing

- Y-branch pipe with vent and immobilising screw

- Special adapter DN 80 for elastic connection of the delivery line with 108 – 114.3 mm outside pipe diameter (optional 88 – 93 mm)

- Connecting flange for stop valve DN 80 PN 16

- 2 pump units

- 3-phase motor: 400 V, 50 Hz

- Degree of protection IP 68

- Integrated permanent motor monitoring

- Blockage-free free flow impeller

- 10 m connection cable

- Level switching

- Pneumatic level switching with 10 m control cable

- Optionally with air bubble injection (accessory)

- Control

- Degree of protection IP 54

- 1.5 m cable and CEE plug (16A) – DDP x.1

- 1.5 m cable and CEE plug (32A) – DDP x.2

- Isolated group alarm and operation signal

- Tested to EN 12050‑1

| Type | Motor power | Key data | Granu lation | Usable volume | Total volume | Weight | Item number | |||||

| P1 | P2 | Current consumption | Voltage | Rev- count | Inlet height Z 1 | Inlet height Z 2 | Top inlet | |||||

| [kW] | [kW] | [A] | [V] | [r/min] | [mm] | [l] | [l] | [l] | [l] | [kg] | ||

| Muli-Star DDP ECO 1.0 | 1.83 | 1.5 | 3.5 | 400 | 1400 | 65 | 65 | 110 | 110 | 150 | 101 | 1202.00.13 |

| Muli-Star DDP 1.1 | 1.83 | 1.5 | 5 | 400 | 1400 | 65 | 65 | 110 | 110 | 150 | 101 | 1202.00.01 |

| Muli-Star DDP 1.2 | 3.45 | 3 | 10 | 400 | 2800 | 65 | 65 | 110 | 110 | 150 | 124 | 1202.00.02 |

| Muli-Star DDP ECO 2.0 | 1.83 | 1.5 | 3.5 | 400 | 1400 | 65 | 95 | 185 | 185 | 300 | 107 | 1202.00.14 |

| Muli-Star DDP 2.1 | 1.83 | 1.5 | 5 | 400 | 1400 | 65 | 95 | 185 | 185 | 300 | 107 | 1202.00.04 |

| Muli-Star DDP 2.2 | 3.45 | 3 | 10 | 400 | 2800 | 65 | 95 | 185 | 185 | 300 | 130 | 1202.00.05 |

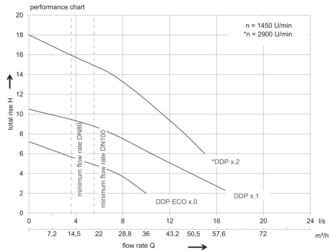

| Type | Delivery head | Delivery flow Q with overall delivery head H | Media temperature | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 4 m | 6 m | 8 m | 10 m | 12 m | 14 m | 16 m | Normal | Maximum | ||

| [m] | [l/s] | [l/s] | [l/s] | [l/s] | [l/s] | [l/s] | [l/s] | [°C] | [°C] | |

| Muli-Star DDP ECO 1.0 | 2 – 4.8 | 7.5 | 3.0 | 40 | 65 | |||||

| Muli-Star DDP 1.1 | 4 – 9.5 | 14.44 | 11.0 | 7.5 | 1.5 | 40 | 65 | |||

| Muli-Star DDP 1.2 | 6 – 16 | 15.0 | 13.3 | 11.38 | 9.4 | 7.1 | 3.51 | 40 | 65 | |

| Muli-Star DDP ECO 2.0 | 2 – 4.8 | 7.5 | 3.0 | 40 | 65 | |||||

| Muli-Star DDP 2.1 | 4 – 9.5 | 14.44 | 11.0 | 7.5 | 1.5 | 40 | 65 | |||

| Muli-Star DDP 2.2 | 6 – 16 | 15.0 | 13.3 | 11.38 | 9.4 | 7.1 | 3.51 | 40 | 65 | |

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.13

- BIM Data (ifc) - 1202.00.13

- Technical Drawing Dxf - 1202.00.13

- Data sheet 1202.00.13

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.01

- BIM Data (ifc) - 1202.00.13

- Technical Drawing Dxf - 1202.00.01

- 3D-Model (igs) - 1202.00.01

- Data sheet 1202.00.01

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.02

- BIM Data (ifc) - 1202.00.02

- Technical Drawing Dxf - 1202.00.02

- 3D-Model (igs) - 1202.00.02

- Data sheet 1202.00.02

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.14

- BIM Data (ifc) - 1202.00.14

- Technical Drawing Dxf - 1202.00.14

- Data sheet 1202.00.14

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.04

- BIM Data (ifc) - 1202.00.14

- Technical Drawing Dxf - 1202.00.04

- 3D-Model (igs) - 1202.00.04

- Data sheet 1202.00.04

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.05

- BIM Data (ifc) - 1202.00.05

- Technical Drawing Dxf - 1202.00.05

- 3D-Model (igs) - 1202.00.05

- Data sheet 1202.00.05

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

| Type | Motor power | Key data | Granu lation | Usable volume | Total volume | Weight | Item number | |||||

| P1 | P2 | Current consumption | Voltage | Rev- count | Inlet height Z 1 | Inlet height Z 2 | Top inlet | |||||

| [kW] | [kW] | [A] | [V] | [r/min] | [mm] | [l] | [l] | [l] | [l] | [kg] | ||

| Muli-Star DDP ECO 1.0 | 1.83 | 1.5 | 3.5 | 400 | 1400 | 65 | 65 | 110 | 110 | 150 | 101 | 1202.00.13 |

| Muli-Star DDP 1.1 | 1.83 | 1.5 | 5 | 400 | 1400 | 65 | 65 | 110 | 110 | 150 | 101 | 1202.00.01 |

| Muli-Star DDP 1.2 | 3.45 | 3 | 10 | 400 | 2800 | 65 | 65 | 110 | 110 | 150 | 124 | 1202.00.02 |

| Muli-Star DDP ECO 2.0 | 1.83 | 1.5 | 3.5 | 400 | 1400 | 65 | 95 | 185 | 185 | 300 | 107 | 1202.00.14 |

| Muli-Star DDP 2.1 | 1.83 | 1.5 | 5 | 400 | 1400 | 65 | 95 | 185 | 185 | 300 | 107 | 1202.00.04 |

| Muli-Star DDP 2.2 | 3.45 | 3 | 10 | 400 | 2800 | 65 | 95 | 185 | 185 | 300 | 130 | 1202.00.05 |

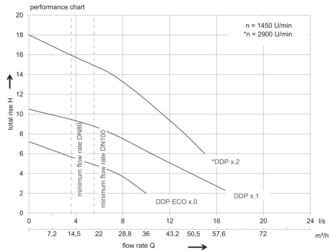

| Type | Delivery head | Delivery flow Q with overall delivery head H | Media temperature | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 4 m | 6 m | 8 m | 10 m | 12 m | 14 m | 16 m | Normal | Maximum | ||

| [m] | [l/s] | [l/s] | [l/s] | [l/s] | [l/s] | [l/s] | [l/s] | [°C] | [°C] | |

| Muli-Star DDP ECO 1.0 | 2 – 4.8 | 7.5 | 3.0 | 40 | 65 | |||||

| Muli-Star DDP 1.1 | 4 – 9.5 | 14.44 | 11.0 | 7.5 | 1.5 | 40 | 65 | |||

| Muli-Star DDP 1.2 | 6 – 16 | 15.0 | 13.3 | 11.38 | 9.4 | 7.1 | 3.51 | 40 | 65 | |

| Muli-Star DDP ECO 2.0 | 2 – 4.8 | 7.5 | 3.0 | 40 | 65 | |||||

| Muli-Star DDP 2.1 | 4 – 9.5 | 14.44 | 11.0 | 7.5 | 1.5 | 40 | 65 | |||

| Muli-Star DDP 2.2 | 6 – 16 | 15.0 | 13.3 | 11.38 | 9.4 | 7.1 | 3.51 | 40 | 65 | |

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.13

- BIM Data (ifc) - 1202.00.13

- Technical Drawing Dxf - 1202.00.13

- Data sheet 1202.00.13

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.01

- BIM Data (ifc) - 1202.00.13

- Technical Drawing Dxf - 1202.00.01

- 3D-Model (igs) - 1202.00.01

- Data sheet 1202.00.01

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.02

- BIM Data (ifc) - 1202.00.02

- Technical Drawing Dxf - 1202.00.02

- 3D-Model (igs) - 1202.00.02

- Data sheet 1202.00.02

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.14

- BIM Data (ifc) - 1202.00.14

- Technical Drawing Dxf - 1202.00.14

- Data sheet 1202.00.14

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.04

- BIM Data (ifc) - 1202.00.14

- Technical Drawing Dxf - 1202.00.04

- 3D-Model (igs) - 1202.00.04

- Data sheet 1202.00.04

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products

- [Declaration of Performance DOP] BD-G1-3007

- Instruction for use

- Brochure Wastewater lifting plant and Pumping stations for trade and industry

- 3D-Model (dwg) - 1202.00.05

- BIM Data (ifc) - 1202.00.05

- Technical Drawing Dxf - 1202.00.05

- 3D-Model (igs) - 1202.00.05

- Data sheet 1202.00.05

- [Environmental Product Declaration (EPD)] Rotomoulded containers for drainage products