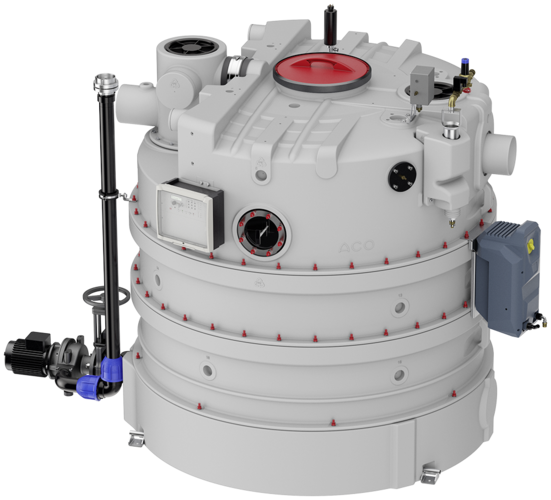

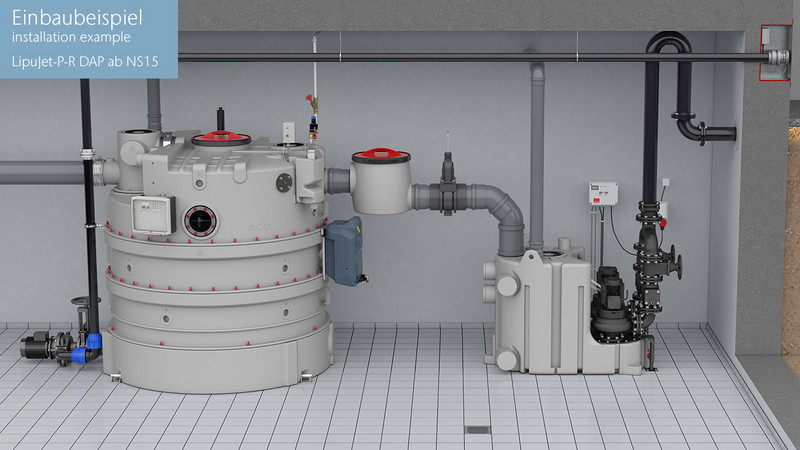

Grease Separator LipuJet-P-RAP extension stage 3

Product benefits

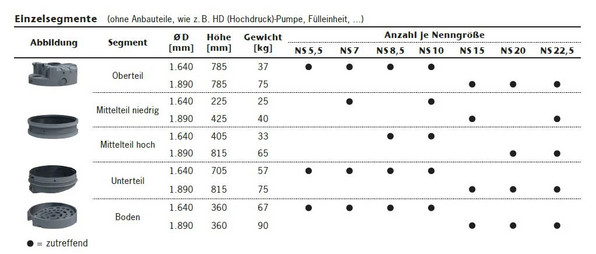

- Easy to transport and assemble (incorporation in individual segments)

- Optimum insertion dimension

- Easier handling due to weight reduction

- Rotatable inlet fitting and stretchable odor trap

- Multifunctional container

- Emptying, cleaning and filling without odor nuisance

- Individually adjustable pre- and after-cleaning times

- Hydromechanical high-pressure interior cleaning – cold water connection only necessary

Product information

- Grease separator according to EN 1825 - Nominal Sizes (5,5-22.5)

- With integrated sludge trap

- Container made of polyethylene, in segment construction

- For indoor installation – frost-free

- Suction and drainage sump

- Odour-tight maintenance opening (clear width Ø450 mm)

- Odour-tight inspection opening through Inlet and outlet

- Central connection for direct suction with fixed coupling and blind coupling

- Inspection window with wiper

- High-pressure internal cleaning:

- Motor-driven high-pressure spray head (360° cleaning over two axles)

- HP (high pressure) pump (nominal pressure 175 bar)

- Filling unit (components with DVGW and KIWA approvals) for automatic refilling:

- Free-flow valve

- Pressure reducer with dirt trap

- Solenoid valve

- Odour trap

- Level measurement via pneumatic pressure measurement including bubbler injection:

- Pneumatic box with miniature compressor and pressure sensor

- Pitot tube

- Shut-off valve in front of the disposal pump

- Disposal pump:

- Vortex impeller design

- Three-phase motor

- Delivery data according to performance diagram

- Control with connection cable 1.5 m

- And CEE plug 16 A including phase changer, protection class IP 54

- Pipe connectors on the inlet and outlet with transition seal for pipe OD 200 mm (NS 15-22.5) / OD 160mm (NS 5.5-10)

- Execution right or left / following components are to be operated on the right or left to the central axis:

- Inspection window

- Direct suction

- Filling unit

- High pressure spray head

- HP pump

- Pneumatic box

- Control

- Declaration of Performance (DoP) No: BD-G1-1025

- Connections:

- Inlet and outlet OD 200mm (NS 15-22.5) / OD 160mm (NS 5.5-10)

- Vent DN100/OD110 mm

- Direct suction with fixed coupling Storz-B/2½" and blind coupling

- Water connection filling unit Rp ¾"

- Bottom outlet Rp1"

- Electrical connection:

- 400V/50Hz/16A/8.0kW

- Fusing: 3x16A (slow) or according to local conditions

Operation side: Right-hand

| Nominal size | Nominal width | Contents | Weight | Item number | |||

| Sludge trap | Grease store | Overall | Empty | Full | |||

| [l] | [l] | [l] | [kg] | [kg] | |||

| NS 15 | DN 200 | 1550 | 600 | 3130 | 330 | 3460 | 3515.54.00 |

| NS 20 | DN 200 | 2020 | 800 | 4070 | 350 | 4420 | 3520.54.00 |

| NS 22.5 | DN 200 | 2550 | 1000 | 5000 | 400 | 5400 | 3525.54.00 |

Operation side: Left

| Nominal size | Nominal width | Contents | Weight | Item number | |||

| Sludge trap | Grease store | Overall | Empty | Full | |||

| [l] | [l] | [l] | [kg] | [kg] | |||

| NS 15 | DN 200 | 1550 | 600 | 3130 | 330 | 3460 | 3515.54.10 |

| NS 20 | DN 200 | 2020 | 800 | 4070 | 350 | 4420 | 3520.54.10 |

| NS 22.5 | DN 200 | 2550 | 1000 | 5000 | 400 | 5400 | 3525.54.10 |

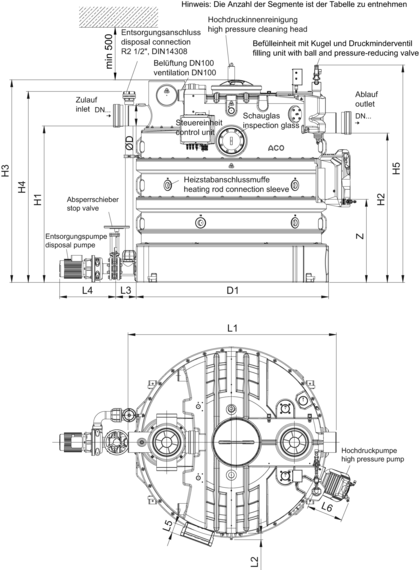

| Item number | Nominal size | Dimensions | |||||||||||||

| L1 | L2 | L3 | L4 | L5 | L6 | H1 | H2 | H3 | H4 | H5 | D | D1 | Z/Anzahl Segmente | ||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | |||

| 3515.54.00 | NS 15 | 2500 | 65 | 210 | 590 | 160 | 360 | 1535 | 1465 | 1990 | 1870 | 2150 | 200 | 1890 | 4 |

| 3515.54.10 | NS 15 | 2500 | 65 | 210 | 590 | 160 | 360 | 1535 | 1465 | 1990 | 1870 | 2150 | 200 | 1890 | 4 |

| 3520.54.00 | NS 20 | 2500 | 65 | 210 | 590 | 160 | 360 | 1925 | 1855 | 2380 | 2260 | 2540 | 200 | 1890 | 4 |

| 3520.54.10 | NS 20 | 2500 | 65 | 210 | 590 | 160 | 360 | 1925 | 1855 | 2380 | 2260 | 2540 | 200 | 1890 | 4 |

| 3525.54.00 | NS 22.5 | 2500 | 65 | 210 | 590 | 160 | 360 | 2305 | 2235 | 2760 | 2640 | 2910 | 200 | 1890 | 5 |

| 3525.54.10 | NS 22.5 | 2500 | 65 | 210 | 590 | 160 | 360 | 2305 | 2235 | 2760 | 2640 | 2910 | 200 | 1890 | 5 |

Sampling pot DN 150

Suitable for

- Grease separator LipuJet-P/LipuSmart-P

- NS 5.5 – 10

- Starch separator FapuJet-P-OAP

- NS 2

Description

- For installation of horizontal pipes DN 150 to grease separator

- Round shape with

- Coupling socket seal (material SBR) on inlet and spigot on outflow

- Odour-proof maintenance opening DN 450

- Weight: 10.1 kg

Sampling pot DN 150

Suitable for

- Grease separator LipuJet-P/LipuSmart-P

- NS 5.5 – 10

- Starch separator FapuJet-P-OAP

- NS 2

Description

- For installation in vertical pipes DN 150 going to grease separator

- Round shape with

- Coupling socket seal (material SBR) on inlet and spigot on outflow

- Odour-proof maintenance opening DN 450

- Weight: 10.1 kg

Grease layer thickness measuring device

Suitable for

- LipuJet-P

- Oval NS 1 – 10

- Round NS 2 – 22,5

- LipuJet-S

- Oval NS 1 – 10

- Round NS 2 – 20

- LipuSmart-P

- Oval NS 1 – 10

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (80%) and advance warning of fill level (50%)

- With visual display of fill level

- With heated probe rod to increase reliability of operation

- Operating voltage: 230VAC/5 VA

- Max consumption approx. 12W

- Weight: 2.8 kg

Coarse trap DN 150

Suitable for

- Grease separator LipuJet-P/LipuSmart-P

- NS 5.5 – 10

- Starch separator FapuJet-P-OAP

- NS 2

Description

- For installation in vertical pipes DN 150 going to grease separator

- Round shape with

- Coupling socket seal (material SBR) on inlet and spigot on outflow

- Basket made from stainless steel, material grade 316 to retain coarse substances

- Odour-proof maintenance opening DN 450

- Weight: 12.6 kg

Coarse trap DN 200

Suitable for

- Grease separator LipuJet-P

- NS 15 – 22,5

Description

- For installation in vertical pipes DN 200 going to grease separator

- Round shape with

- Coupling socket seal (material SBR) on inlet and spigot on outflow

- Basket made from stainless steel, material grade 316 to retain coarse substances

- Odour-proof maintenance opening DN 450

- Weight: 9.9 kg

Stop valve

Suitable for

- Grease separators for free-standing installation

- Starch separator for free-standing installation

Description

- Made of cast iron

- Penstock plate, spindle made from stainless steel, material grade 304

- DN 150

- Length (L): 60 mm

- Spindle travel (H1 – H2): 478 – 639 mm

- Manual wheel diameter: 200 mm

- Weight: 29.4 kg

Connection box

Suitable for

- Grease separators

- LipuMax-P-D/DM/DA

- LipuJet-P-OD/RD/SD/OM/OMP/RM/RMP

- LipuJet-S-OD/RD/SD/OM/OMP/RM/RMP

- Stach seperators FapuMax-P-DA

- Oil separators Coalisator-P

- LipuLift-P-D/-DA/-DAP

Description

- For evacuation connection DN 80

- Made from stainless steel, material grade 304

- "On wall" version

- Door stop

- Choice of left or right

- Lockable door

- Dimensions (width x height x depth): 370 x 330 x 250 mm

- Weight: 10.4 kg

Connection box

Suitable for

- Grease separator

- Starch separators

- LipuLift-P-D/-DA/-DAP

Description

- For disposal connection, pendulum gas line (if necessary) and remote control

- From stainless steel, material grade 304

- "Surface mounted” version

- Glass beaded front

- Lockable door, left limit stop

- Dimensions W x H x D: 300 x 725 x 160 mm

- Weight: 10 kg

ACO Ozone Generator

Suitable for

- Grease separators, indoors

- Grease separators, outdoors

- Lifting stations

- Pumping stations

Description

- ACO Ozone minimizes odors that can arise from grease seperators, lifting plants and pumping stations

- Material: acid-resistant stainless steel

Consists:

- ACO Ozone - ozone generator

- Size (L x W x H): 270 x 100 x 85 mm

- Nominal voltage 230 V / 50 Hz

- Degree of protection IP20

- ACO Ozone pump - feed pump

- Size (L x W x H): 160 x 90 x 90 mm

- Integrated filter

- Nominal voltage 230 V / 50 Hz

- Degree of protection IP54

- ACO Ozone bracket - wall bracket

- Size (L x W x H): 295 x 110 x 90 mm

- Hoses

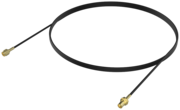

Message system with GSM module

Suitable for

- All grease separators

- Grease layer thickness measuring device

- Pre-tank plants

- Technical processing systems

- Quatrix-K backflow preventer type 3F

- Sinkamat-K (underfloor) duo

- Muli lifting units

- Pumping stations

- Installation sets

Description

- Parameter via app (Android & iOs)

- Mains-independent alarm via 12V lead-gel battery

- Optical and acoustic alarm message

- Freely configurable inputs

- 6 digital inputs with LED status display

- 1 analogue

- 1 alarm output 12 V

- Alarm forwarding via SMS to mobile phones

- For mounting outside the hazardous area

- Housing: 192 x 150(with cable gland) x 100 mm (WxHxD)

- Protective doctor: IP54

- Operating voltage: 230 V/AC 50/60 Hz

- Weight: 2 kg

Operating Logbook

Suitable for

- Grease separator

- For underground installation

- For free-standing installation

Description

- Contents: Check-list and standard forms to document in-house monitoring, maintenance and disposal relating to the plant as required by DIN 4040-100

- Format: A4 with double filing rings

- Size: 60 pages

- Laid out to cover 5 years

- Weight: 0.3 kg

Operation side: Right-hand

| Nominal size | Nominal width | Contents | Weight | Item number | |||

| Sludge trap | Grease store | Overall | Empty | Full | |||

| [l] | [l] | [l] | [kg] | [kg] | |||

| NS 15 | DN 200 | 1550 | 600 | 3130 | 330 | 3460 | 3515.54.00 |

| NS 20 | DN 200 | 2020 | 800 | 4070 | 350 | 4420 | 3520.54.00 |

| NS 22.5 | DN 200 | 2550 | 1000 | 5000 | 400 | 5400 | 3525.54.00 |

Operation side: Left

| Nominal size | Nominal width | Contents | Weight | Item number | |||

| Sludge trap | Grease store | Overall | Empty | Full | |||

| [l] | [l] | [l] | [kg] | [kg] | |||

| NS 15 | DN 200 | 1550 | 600 | 3130 | 330 | 3460 | 3515.54.10 |

| NS 20 | DN 200 | 2020 | 800 | 4070 | 350 | 4420 | 3520.54.10 |

| NS 22.5 | DN 200 | 2550 | 1000 | 5000 | 400 | 5400 | 3525.54.10 |

| Item number | Nominal size | Dimensions | |||||||||||||

| L1 | L2 | L3 | L4 | L5 | L6 | H1 | H2 | H3 | H4 | H5 | D | D1 | Z/Anzahl Segmente | ||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | |||

| 3515.54.00 | NS 15 | 2500 | 65 | 210 | 590 | 160 | 360 | 1535 | 1465 | 1990 | 1870 | 2150 | 200 | 1890 | 4 |

| 3515.54.10 | NS 15 | 2500 | 65 | 210 | 590 | 160 | 360 | 1535 | 1465 | 1990 | 1870 | 2150 | 200 | 1890 | 4 |

| 3520.54.00 | NS 20 | 2500 | 65 | 210 | 590 | 160 | 360 | 1925 | 1855 | 2380 | 2260 | 2540 | 200 | 1890 | 4 |

| 3520.54.10 | NS 20 | 2500 | 65 | 210 | 590 | 160 | 360 | 1925 | 1855 | 2380 | 2260 | 2540 | 200 | 1890 | 4 |

| 3525.54.00 | NS 22.5 | 2500 | 65 | 210 | 590 | 160 | 360 | 2305 | 2235 | 2760 | 2640 | 2910 | 200 | 1890 | 5 |

| 3525.54.10 | NS 22.5 | 2500 | 65 | 210 | 590 | 160 | 360 | 2305 | 2235 | 2760 | 2640 | 2910 | 200 | 1890 | 5 |

Sampling pot DN 150

Suitable for

- Grease separator LipuJet-P/LipuSmart-P

- NS 5.5 – 10

- Starch separator FapuJet-P-OAP

- NS 2

Description

- For installation of horizontal pipes DN 150 to grease separator

- Round shape with

- Coupling socket seal (material SBR) on inlet and spigot on outflow

- Odour-proof maintenance opening DN 450

- Weight: 10.1 kg

Sampling pot DN 150

Suitable for

- Grease separator LipuJet-P/LipuSmart-P

- NS 5.5 – 10

- Starch separator FapuJet-P-OAP

- NS 2

Description

- For installation in vertical pipes DN 150 going to grease separator

- Round shape with

- Coupling socket seal (material SBR) on inlet and spigot on outflow

- Odour-proof maintenance opening DN 450

- Weight: 10.1 kg

Grease layer thickness measuring device

Suitable for

- LipuJet-P

- Oval NS 1 – 10

- Round NS 2 – 22,5

- LipuJet-S

- Oval NS 1 – 10

- Round NS 2 – 20

- LipuSmart-P

- Oval NS 1 – 10

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (80%) and advance warning of fill level (50%)

- With visual display of fill level

- With heated probe rod to increase reliability of operation

- Operating voltage: 230VAC/5 VA

- Max consumption approx. 12W

- Weight: 2.8 kg

Coarse trap DN 150

Suitable for

- Grease separator LipuJet-P/LipuSmart-P

- NS 5.5 – 10

- Starch separator FapuJet-P-OAP

- NS 2

Description

- For installation in vertical pipes DN 150 going to grease separator

- Round shape with

- Coupling socket seal (material SBR) on inlet and spigot on outflow

- Basket made from stainless steel, material grade 316 to retain coarse substances

- Odour-proof maintenance opening DN 450

- Weight: 12.6 kg

Coarse trap DN 200

Suitable for

- Grease separator LipuJet-P

- NS 15 – 22,5

Description

- For installation in vertical pipes DN 200 going to grease separator

- Round shape with

- Coupling socket seal (material SBR) on inlet and spigot on outflow

- Basket made from stainless steel, material grade 316 to retain coarse substances

- Odour-proof maintenance opening DN 450

- Weight: 9.9 kg

Stop valve

Suitable for

- Grease separators for free-standing installation

- Starch separator for free-standing installation

Description

- Made of cast iron

- Penstock plate, spindle made from stainless steel, material grade 304

- DN 150

- Length (L): 60 mm

- Spindle travel (H1 – H2): 478 – 639 mm

- Manual wheel diameter: 200 mm

- Weight: 29.4 kg

Connection box

Suitable for

- Grease separators

- LipuMax-P-D/DM/DA

- LipuJet-P-OD/RD/SD/OM/OMP/RM/RMP

- LipuJet-S-OD/RD/SD/OM/OMP/RM/RMP

- Stach seperators FapuMax-P-DA

- Oil separators Coalisator-P

- LipuLift-P-D/-DA/-DAP

Description

- For evacuation connection DN 80

- Made from stainless steel, material grade 304

- "On wall" version

- Door stop

- Choice of left or right

- Lockable door

- Dimensions (width x height x depth): 370 x 330 x 250 mm

- Weight: 10.4 kg

Connection box

Suitable for

- Grease separator

- Starch separators

- LipuLift-P-D/-DA/-DAP

Description

- For disposal connection, pendulum gas line (if necessary) and remote control

- From stainless steel, material grade 304

- "Surface mounted” version

- Glass beaded front

- Lockable door, left limit stop

- Dimensions W x H x D: 300 x 725 x 160 mm

- Weight: 10 kg

ACO Ozone Generator

Suitable for

- Grease separators, indoors

- Grease separators, outdoors

- Lifting stations

- Pumping stations

Description

- ACO Ozone minimizes odors that can arise from grease seperators, lifting plants and pumping stations

- Material: acid-resistant stainless steel

Consists:

- ACO Ozone - ozone generator

- Size (L x W x H): 270 x 100 x 85 mm

- Nominal voltage 230 V / 50 Hz

- Degree of protection IP20

- ACO Ozone pump - feed pump

- Size (L x W x H): 160 x 90 x 90 mm

- Integrated filter

- Nominal voltage 230 V / 50 Hz

- Degree of protection IP54

- ACO Ozone bracket - wall bracket

- Size (L x W x H): 295 x 110 x 90 mm

- Hoses

Message system with GSM module

Suitable for

- All grease separators

- Grease layer thickness measuring device

- Pre-tank plants

- Technical processing systems

- Quatrix-K backflow preventer type 3F

- Sinkamat-K (underfloor) duo

- Muli lifting units

- Pumping stations

- Installation sets

Description

- Parameter via app (Android & iOs)

- Mains-independent alarm via 12V lead-gel battery

- Optical and acoustic alarm message

- Freely configurable inputs

- 6 digital inputs with LED status display

- 1 analogue

- 1 alarm output 12 V

- Alarm forwarding via SMS to mobile phones

- For mounting outside the hazardous area

- Housing: 192 x 150(with cable gland) x 100 mm (WxHxD)

- Protective doctor: IP54

- Operating voltage: 230 V/AC 50/60 Hz

- Weight: 2 kg

Operating Logbook

Suitable for

- Grease separator

- For underground installation

- For free-standing installation

Description

- Contents: Check-list and standard forms to document in-house monitoring, maintenance and disposal relating to the plant as required by DIN 4040-100

- Format: A4 with double filing rings

- Size: 60 pages

- Laid out to cover 5 years

- Weight: 0.3 kg